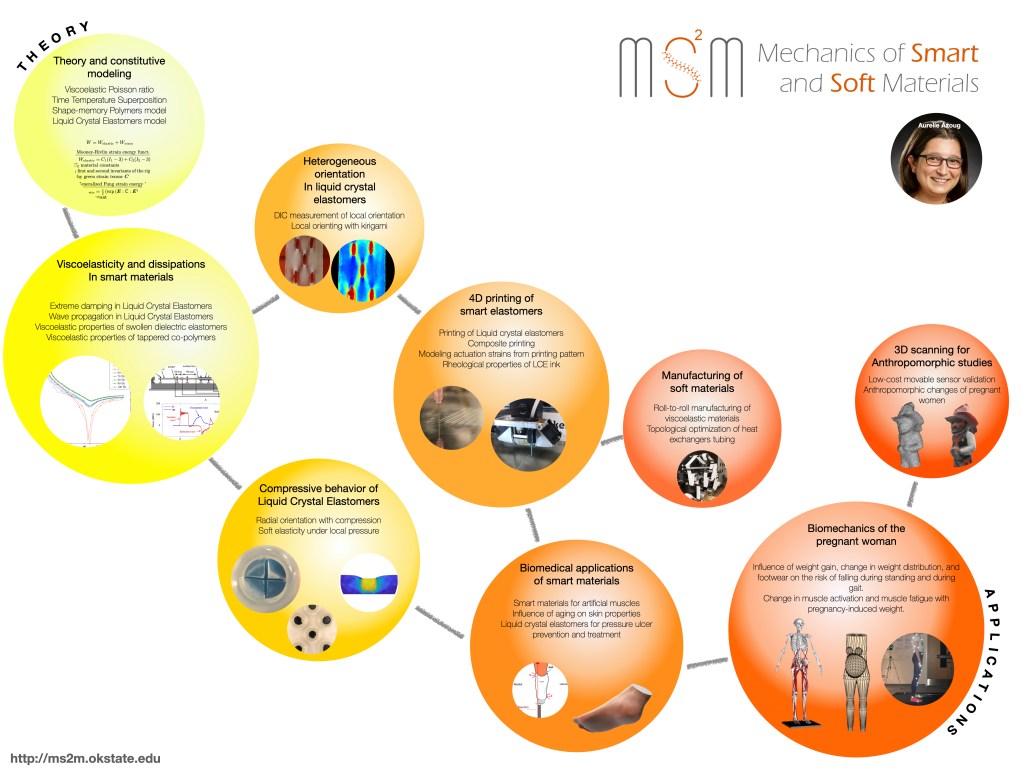

The MS2M = Mechanics of Smart and Soft Materials Lab focuses the fundamental understanding of the formation, deformation, dissipations, and evolution mechanisms of smart elastomers and soft tissues. This understanding will emerge from the combination of targeted experimental measurements at multiple scales and corresponding simulation approaches. The research focuses on areas of engineering where the mechanics of a soft material largely impacts the ultimate behavior of the system. We are particularly interested in the time-dependent mechanical behavior of liquid crystal elastomers, their damping abilities, and their use for bioengineering applications. We also aim to define interventions to mitigate the high risk of falling during pregnancy, using musculoskeletal modeling of the pregnant body and gait measurements.

Mechanics of smart elastomers: Liquid Crystal Elastomers

Liquid crystal elastomers (LCEs) are smart (or multifunctional) materials containing liquid crystalline molecules that can orient into an ordered structure or disorient. The stimulus, e.g. light, heat, or electric current, will prompt this orientation or disorientation at the molecular level, which will result in a macroscopic deformation. Their thermo-mechanical behavior exhibits multiple phenomena linked to the change of order of the liquid crystals in the microstructure, such as soft elasticity at the polydomain-monodomain transition and actuation at the nematic-isotropic transition. These materials are ideal candidates for various applications: soft actuators, micro-valves, or artificial muscles for instance. Specifically, main-chain LCEs have a high potential for innovative applications due to their performance in terms of shape change and their great flexibility in the preparation procedure. The open questions in this research field cover different areas: chemistry for synthesizing or manufacturing LCEs, physics for identifying specific small-scale mechanisms, and mechanics for optimizing and predicting the macroscopic behavior.

We aim to determine the structure-property relations pertaining to the viscoelastic and dynamic behavior of LCEs.

- Viscoelasticity and soft elasticity in liquid crystal elastomers: constitutive modeling

- Liquid crystal elastomers under compressive loading

- Heterogeneous orientation in liquid crystal elastomers: kirigami and loading directions

- Smooth particle hydrodynamics modeling of mesogen orientation

- Small scale measurement of molecular mobility: Raman and NMR spectroscopy

- Liquid crystal elastomer composites: damping abilities

- Dynamic behavior of liquid crystal elastomers: inflation

Biomechanics

- From 3D scanning to subject-specific musculoskeletal model

- Biomechanics of pregnant women

- Impact of shoe types on quiet stance and gait

- A smart skin for pressure ulcers

- Mechanical loading of skin blood network leading to ulcers

- Unified modeling of the mechanical behavior of brain tissues under various loadings

Manufacturing

4D printing: Direct Ink Writing and Photo-curing

- 4D printing of liquid crystal elastomers

- Photo-curing kinetics

Roll-to-roll manufacturing: impact of web viscoelasticity

- Viscoelastic Poisson’s ratio in webs for roll-to-roll processing

- Viscoelasticity in roll-to-roll lamination

- Viscoelasticity and curing phenomena in roll-to-roll nanoimprint lithography

- Viscoelastic web curl during storage of webs in wound rolls

Soft Robotics

- Worm pneumatic soft robot: linear motion

- Spider pneumatic soft robot: linear and slow rotating motion

- Best pneumatic soft robot: linear and rotation motion

Previous projects

Micromechanical modeling of UHMWPE fibers