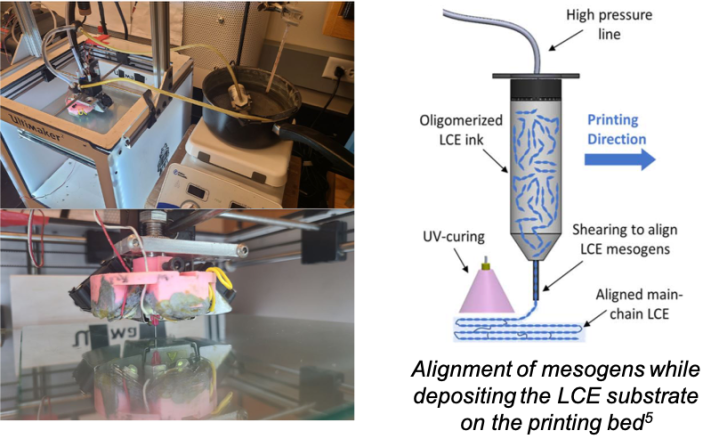

Liquid Crystal Elastomers (LCEs) are active smart materials that exhibit reversible shape changes, or actuation, via the transition between the nematic or liquid crystal state and the isotropic state with the application of heat, light, magnetic field, etc. 4D printing is a form of 3D printing involving smart materials and allows for a change in shape in the post-fabrication phase. The current 4D printing techniques rely predominantly on structure and often on multi-material printing. In this study, we explore the actuation and the viscoelastic mechanical behavior of single-material (LCE) 3D-printed structures, controlling printing parameters such as printing speed, printing angle, etc.

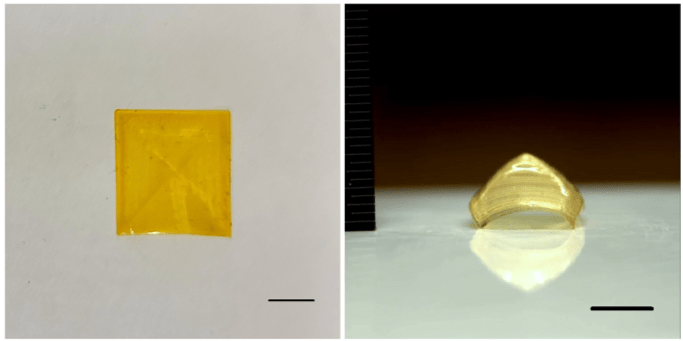

The actuation strain of 4D-printed LCEs increases with printing speed, reaching as high as 42%. In addition, 4D-printed LCEs tend to bend more when printed at higher printing angles. Young’s, storage, and loss moduli increase with printing speed up to a threshold, where the quality of the print decreases. We also found that 4D-printed LCEs exhibit higher moduli than bulk LCEs, due to liquid crystals alignment. Young’s, storage, and loss moduli decrease with the printing angle, showing the influence of the liquid crystal preferred direction on the mechanical properties. By precisely regulating printing speed and angle, we fabricated 2D contracting grids, functional hinges, self-folding boxes, 2D rectangles becoming 3D pyramids, and ribbons turning into 3D helices.

These results show the potential of additively-manufactured heat-responsive LCEs capable of reversibly actuating between two pre-programmed shapes for applications in soft robotics, biomedical prosthetics and implants, dynamic

Highly tunable actuation and mechanical properties of 4D-printed nematic liquid crystal elastomers, Z. Siddiqui, J. Smay, A. Azoug, 2022, Mechanics of Materials, 170:104329