The soft elasticity is the increase in strain at constant stress that occurs in liquid crystal elastomers when the deformation is accommodated by liquid crystals reorienting rather than by polymer chains moving. Soft elasticity notably occurs during the polydomain to monodomain transition as well as during the reorientation of a monodomain from one direction to the one of stretching.

We have explored how the soft elasticity interacts with the intrinsic viscoelasticity of the polymer network.

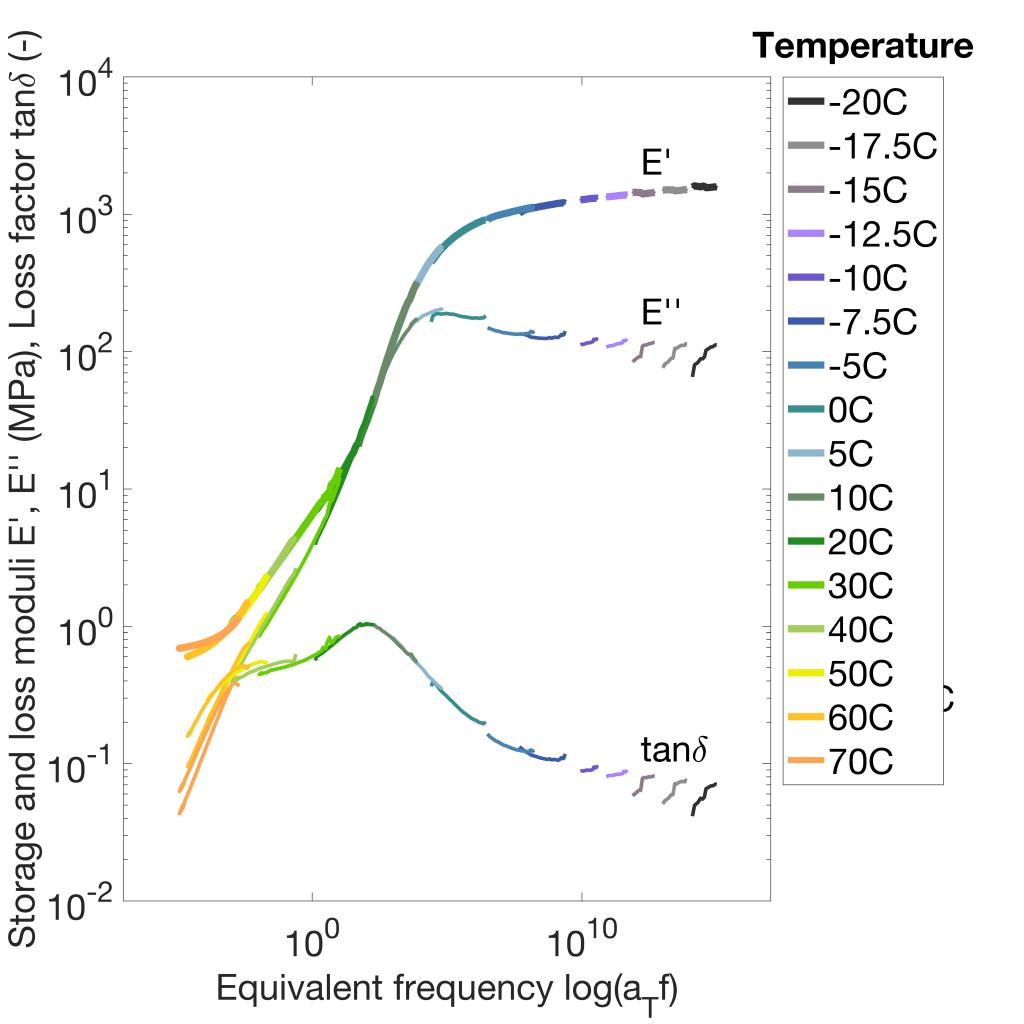

Time-Temperature Superposition of soft elasticity

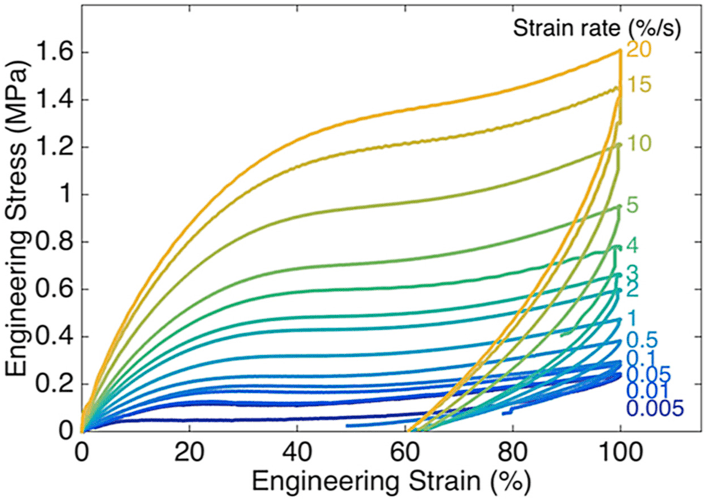

The study aimed at experimentally determining the influence of the viscoelasticity of the material on the soft elasticity phenomenon. I characterized the viscoelasticity with a master curve of the storage modulus, and the phase transition with uniaxial tensile tests at various strain rates and temperatures. Using the time-temperature superposition principle, we showed that the stress and strain values present a linear viscoelastic behavior. For these LCEs, the soft elasticity of the phase transition belongs to the transient part of the behavior. This also reveals the contribution of relaxation mechanisms originating from the liquid crystal orientation. These conclusions provided strong experimental evidence to support a modeling approach of the effective behavior of LCEs.

Small strain modeling of the viscoelastic soft elasticity in tension

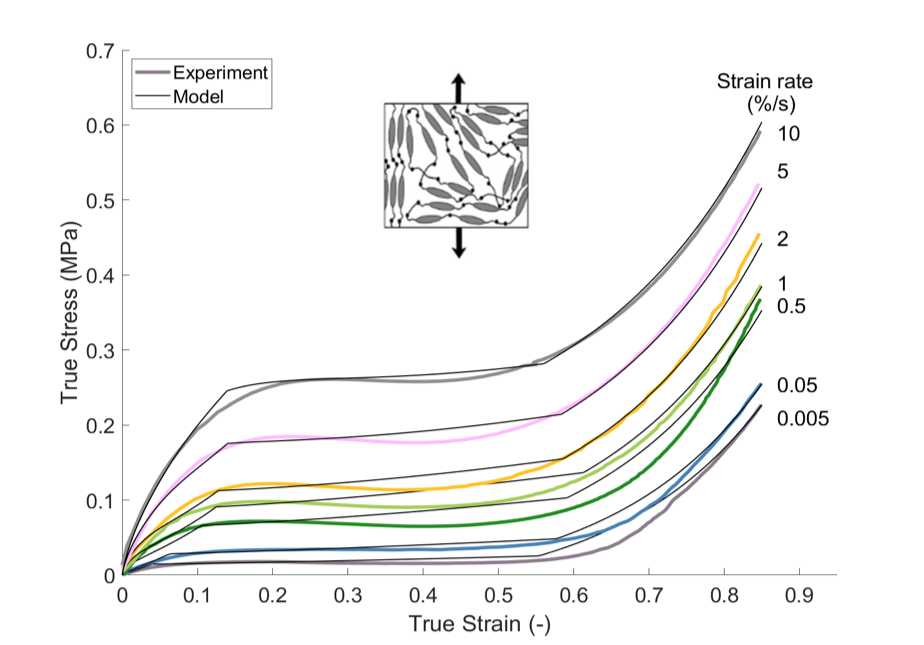

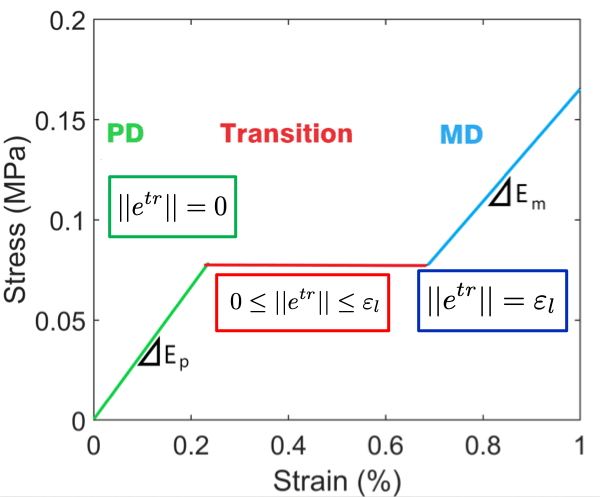

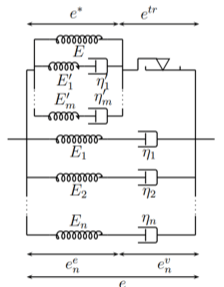

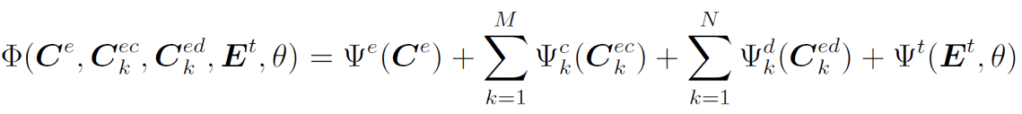

In order to model the viscoelastic, soft elastic behavior of LCEs at room temperature, we are theoretically investigating the dissipation of LCEs to determine the coupling between the viscoelastic mechanisms and the soft elasticity. We expanded the Souza-Auricchio model developed for the superelasticity of Shape Memory Alloys to the soft elasticity of LCEs, integrating viscoelasticity as a coupled or decoupled behavior. A nonlinear generalized Maxwell model represents the relaxation time distribution, considering different combinations of soft elasticity and viscoelasticity effects. In the partially coupled model, some dissipation mechanisms are coupled and will not be active during soft elasticity while others remain decoupled and dissipate during the transition.

The coupling is strong between mesogens and the polymer segments close to them. However, mesogen rotation does not affect the relaxation mechanisms attributed to larger movements of the polymer network further away, which dissipate a significant amount of energy. This division of the viscoelastic mechanisms properly represents the viscoelastic soft elasticity behavior of LCEs.

Coupling between viscoelasticity and soft elasticity in main-chain nematic liquid crystal elastomers, L. Rezaei, G. Scalet, M. Peigney, A. Azoug 2024, Journal of the Mechanics and Physics of Solids, 187:105612

Large strain modeling of the viscoelastic soft elasticity in tension and compression

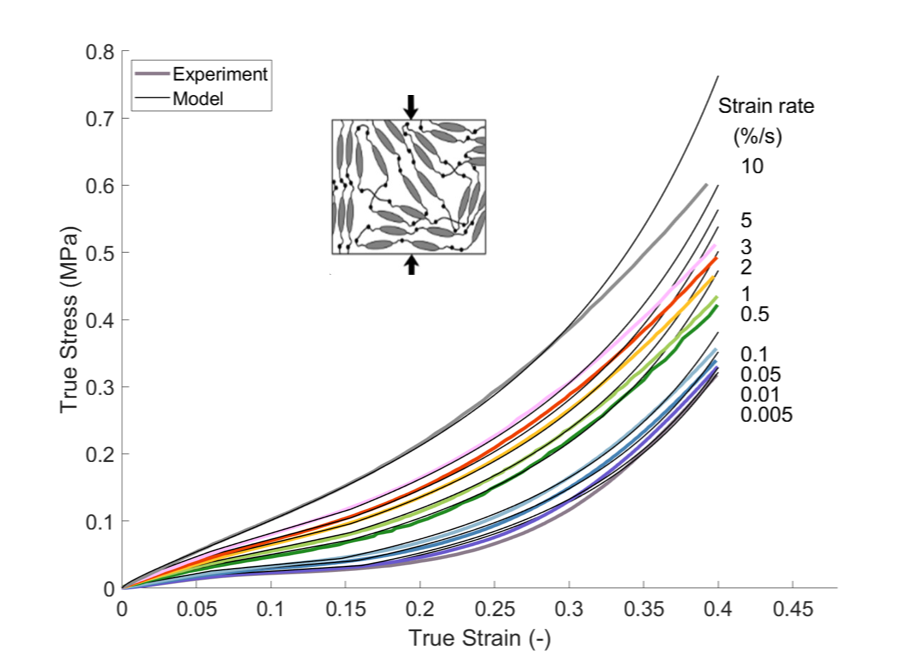

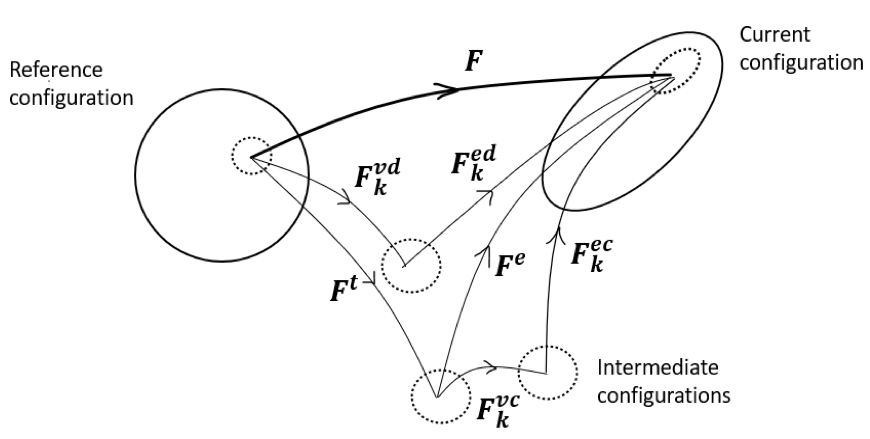

We extended the small strain model to a finite strain framework to accurately predict LCE stress responses under large deformations, notably in compression.

By fitting the finite strain model to experimental data from both tensile and compressive tests, we examined differences in relaxation mechanisms and the effects of mesogen rotation across loading conditions. Finally, the finite strain model was implemented in the finite element software FEAP and FEBio, where its performance was evaluated through a plate-with-a-hole simulation to capture complex stress distributions, demonstrating its ability to predict LCE behavior at various strain rates.